Ginesys ERP is the best manufacturing software for process manufacturing like manufacturing garments, shoes, bags, foods items and more. It is very simple to manage and yet can handle complex requirements of multiple factories, jobbers and warehouses with different items going through different stages of production at various factories. If you are looking for an ERP that is covering all aspects of manufacturing and has a solid distribution and retail management function then Ginesys ERP is the right choice.

Processing

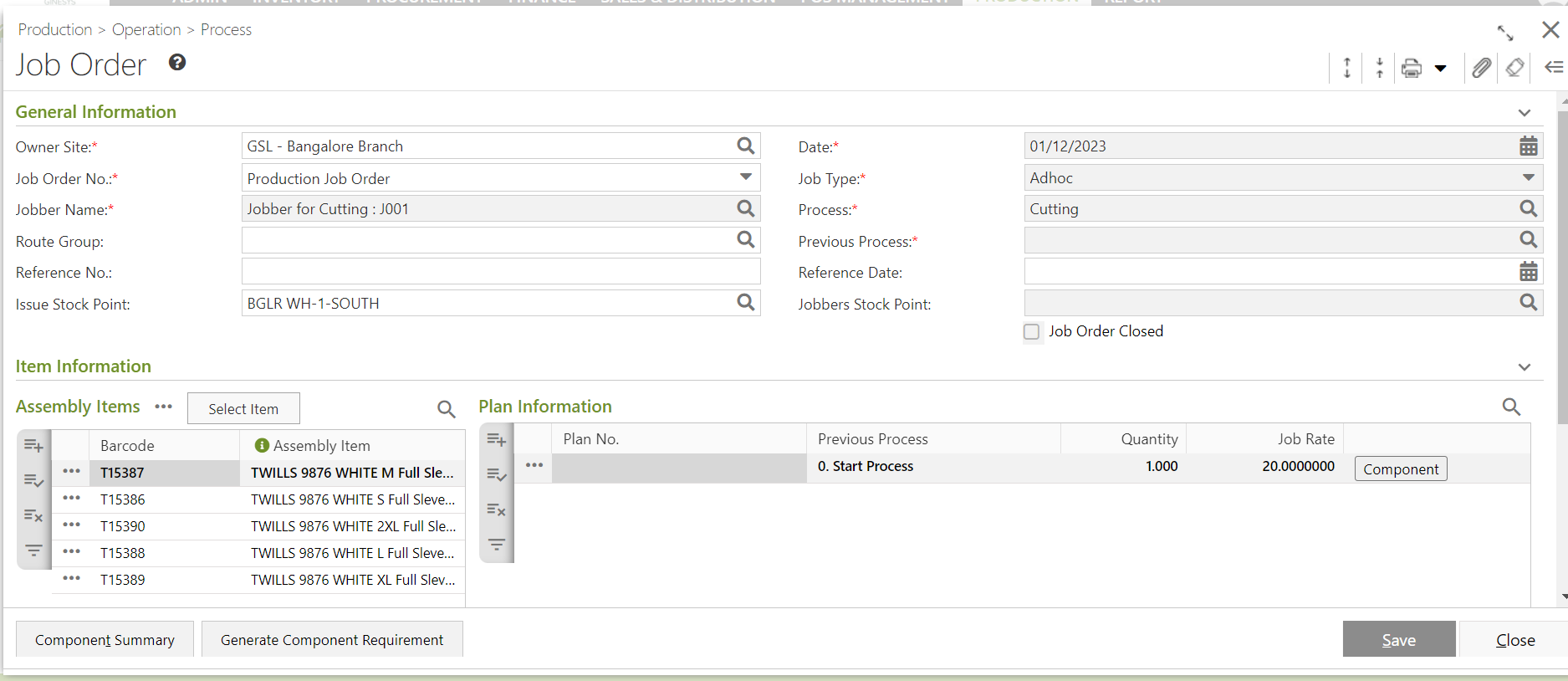

Once the raw materials are received for the first stage of production the raw materials are issued to the first processing unit or job-work factory and from thereon it is a work-in-progress item that is repeatedly issued and received with value additions. For example, in a garment manufacturing process, the stages are dyeing, fabric cutting, stitching, ironing, finishing and packing. Processes and their sequencing depend on the part of the garment being manufactured. The entire process could be done on an outsourced basis with the raw materials being supplied to the contract manufacturer or it could be a managed outsourcing in part with few of the steps happening in-house and few steps being taken up by contractors.

Packing and Shipping

The final stage is putting the finished goods in a bag or box with the labels and ensuring it is ready for dispatch.

Conclusion

Overall, the Ginesys Production module is a great enhancement to India’s most loved Retail ERP. It can handle complex process manufacturing requirements of materials and contract management with ease and give detailed reports on WIP value, production progress and expected delivery and finished goods costing.